How to Make Graphite Moulds with your CNC Machine

This article shows you how to make graphite moulds using your CNC router or milling machine. Having the freedom to make your own moulds allows you to create your own designs from blanks for many craft applications including:

- Glasswork lamping for forming molten glass

- Casting precious metals for decorative jewellery

- Casting mini ingots from recovered gold and silver jewellery

- Casting custom lead weights for fishing

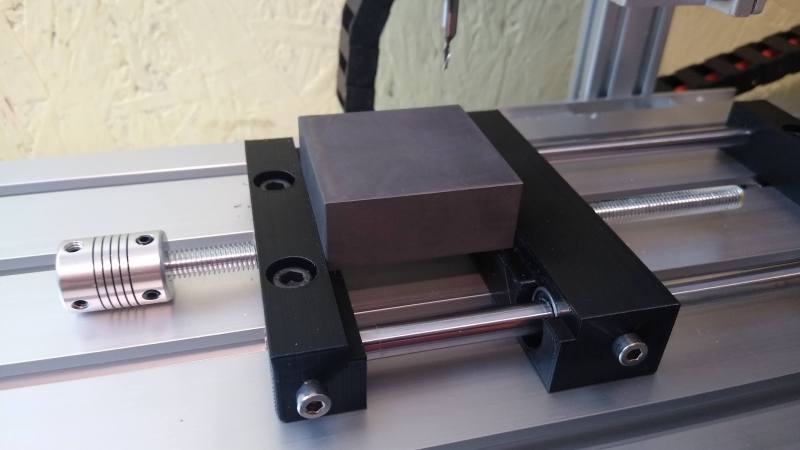

The first thing to do is clamp the workpiece in a vice. I am using a 50x50x20mm graphite blank. The vice is a 3D printed design that can easily be made, or check here for the files.

Tips for CNC Milling Graphite

- Graphite is quite hard on tools in terms of wear, but if you use a coated or carbide bit the wear will not be much of a problem, especially for small batches or one offs.

- Keep cutter feed speeds low to keep dust under control. Use very low feeds like 50mm/min, taking shallow cuts of say 0.5mm per pass.

- Use a brush and a paper dust tray as dust will stick to everything if you vacuum it. Scrunch up the paper catching the dust and dispose.

- Block and fans on your spindle stop spindle blowing the graphite dust around. Keeping the tool loads low will stop overheating.

- Graphite is an excellent dry lubricant to keep the dust if you have an application for it

- Wear a mask as even with dust controls, some will escape into the atmosphere and it’s not a great idea to breathe it, though it is relatively non-toxic.

- Keep spindle speeds slow to keep dust under control

There are a few things to be aware of that can make the process easier and get better results. Graphite Blanks

Credits

Credit to Tini at Atelier Schatzmuschel in Stuttgart. Please follow her work on Instagram, and check out her Etsy store! https://www.instagram.com/atelierscha… https://www.etsy.com/de/shop/AtelierS…

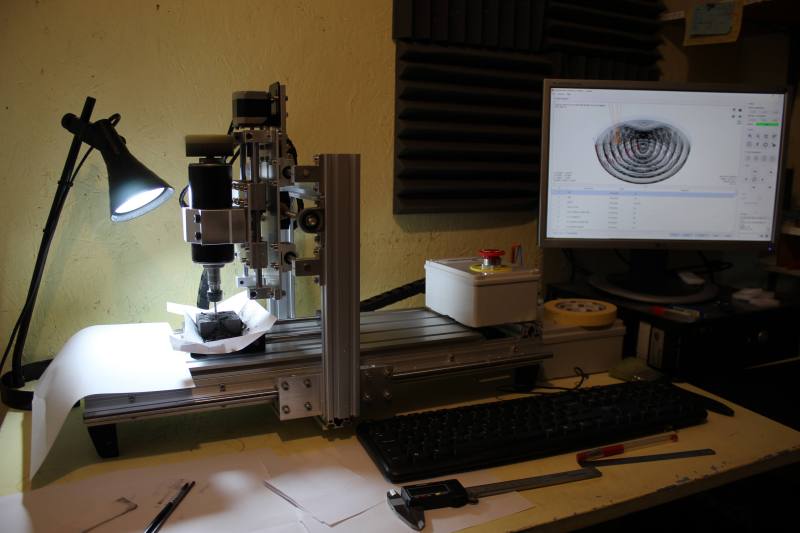

Mould design was made in Solidworks, toolpaths generated in Kiri:Moto and machine control was with Candle.

CAD/CAM/CNC Links below.

More details on the minimillr at https://minimillr.com/

CAD (all free)

Inkscape https://inkscape.org/

Fusion 360 https://www.autodesk.co.uk/products/f…

Onshape https://www.onshape.com/en/platform

TinkerCAD https://www.tinkercad.com/

CAM (all free) Kiri:Moto https://grid.space/kiri/

F-Engrave https://www.scorchworks.com/Fengrave/…

EstlCam https://www.estlcam.de/

Machine Control (all free)

Candle https://github.com/Denvi/Candle (use v1.1.7)

Universal GCode Sender https://winder.github.io/ugs_website/